Tinning of the exterior of wires

We offer custom treatment of cabel a wire ends with tinning. With that, the wires and cables are ready for further processing (eg soldering). Cable harnesses are thus prepared for further production operations either here or are sent directly to the customer.

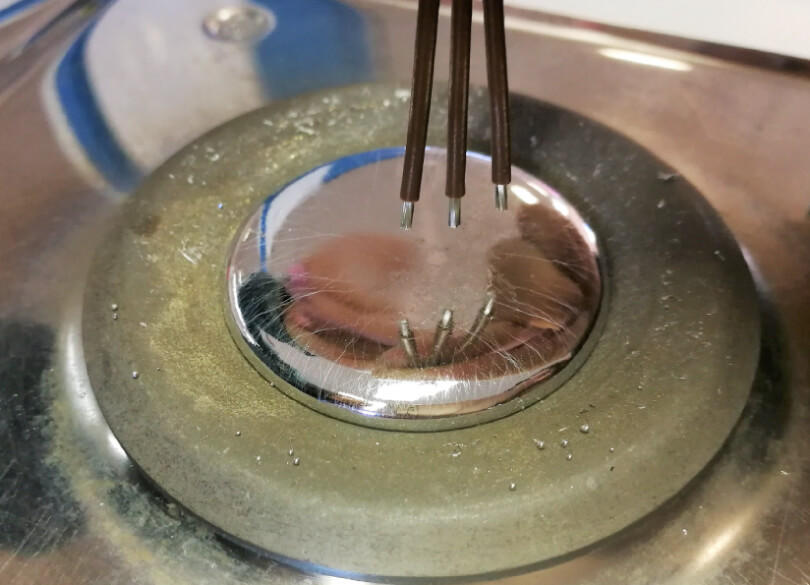

Tinning consists of dipping hot wires into a tin-bath that reaches approximately 300°C.

Tinning is done for several reasons:

- protects the wire from corrosive effects of sulfur in rubber compounds

- protects the wire from the effects of contaminated atmosphere

- facilitates soldering of wires

- improves conductivity

We will adjust the ends of cables and wires with tinning. Wires are thus prepared for further processing eg soldering.